Smart Manufacturing & Industry 5.0

Smart Manufacturing & Industry 5.0

By ProBits Team | 8–10 min read

Report Access Form

Executive Summary

Industry 5.0 represents the next major phase of industrial evolution, emphasizing a human-centric, resilient, and sustainable approach to manufacturing. While Industry 4.0 was predominantly driven by automation, digitization, and productivity gains, it offered limited focus on the workforce and human well-being. Industry 5.0 addresses this gap by placing people at the center of technological advancement.

This new paradigm aims to integrate human creativity, cognitive skills, and decision-making with advanced technologies to build adaptable, efficient, and socially responsible manufacturing systems. At its core, Industry 5.0 aligns industrial practices with the United Nations Sustainable Development Goals (SDGs) and the Triple Bottom Line principles of People, Planet, and Profit.

Industry 5.0 is built around three fundamental pillars:

- Human-Centricity: Technologies are designed to augment human capabilities rather than replace them. Employees are viewed as valuable assets, with human–machine collaboration encouraged to complement strengths and optimize productivity.

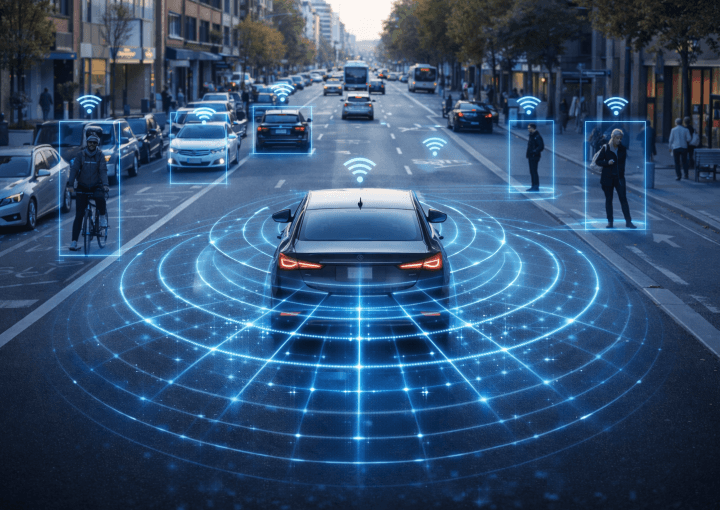

- Resilience: Focuses on building robust and flexible manufacturing systems and supply chains that can seamlessly continue operations during disruptions through automation, digital integration, and adaptive processes.

- Sustainability: Emphasizes the adoption of sustainable practices such as resource efficiency, reduced carbon emissions, and circular economy models across production and service lifecycles.

Smart manufacturing under Industry 5.0 transcends traditional automation by embedding sustainability and human collaboration into digitally connected production systems. It supports high-mix, low-volume production and prioritizes mass customization to meet evolving market demands.

Through the use of advanced digital technologies, Industry 5.0 enables real-time, adaptable operations while enhancing throughput, quality control, and overall efficiency across the manufacturing sector.